HOW DO YOU ADDRESS SAFETY? Are you proactive or reactive? Or do you not do anything because you don’t know what you don’t know?

HOW DO YOU ADDRESS SAFETY? Are you proactive or reactive? Or do you not do anything because you don’t know what you don’t know?

All clubs want to protect their employees from undue harm. Carefully assessing and addressing on-the-job hazards and reviewing federal and state safety compliance regulations and proper safety procedures can help clubs reduce workplace injuries.

The Occupational Safety and Health Administration (OSHA) covers almost all employers and employees in the United States. OSHA’s mission is to assure safe and healthful working conditions for all workers. Covered employers are responsible for complying with OSHA’s “general duty” clause, which states that each employer shall furnish to each employee, “employment and a place of employment that are free from recognized hazards that are causing or likely to cause death or serious physical harm to his employees.” For additional information, see sidebar “OSHA Safety and Health Standards,” page 29.

How to Start a Safety Program

Starting a program may seem like a Herculean task, but it can be achieved by taking the appropriate steps. The first requirement to developing an effective safety program is to ensure buy-in by the board and employees.

This begins by defining the goals and the actions required to achieve them. However, before you develop a safety policy, you must understand the major issues surrounding employee health and safety.

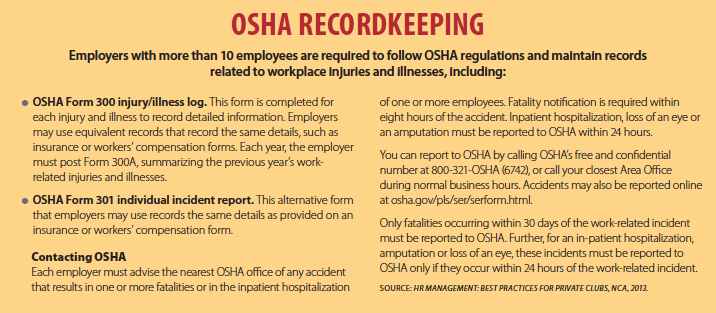

The best way to understand what actions your club should take is to review what has happened in the past. This means reviewing data from previous incidents listed on the workers’ compensation submissions: the employee visits to your local hospital/emergency care center and/or the information on the OSHA 300 and 300A logs (See sidebar “OSHA Recordkeeping,” page 28).

Awareness of injury/illness information will provide you with knowledge necessary to prevent the same incident from occurring again. It also serves as an important reminder to thoroughly document each incident in order to access this data and make sound decisions.

Start a Safety Spreadsheet

Clubs should have a document to collect their safety information. For this, again utilize your workers’ compensation or OSHA 300 logs. It is recommended to go through the past five years to parallel OSHA’s recordkeeping requirements for retaining your 300 and 300A logs. (If you have not recorded your OSHA 300 and 300A logs, start now and list all the data from the past five years.)

In the spreadsheet, create essential categories of data such as: year, date and location of injury, employee department, and type of injury. The types of injury can include: slips, trips, falls, back injury, lifting, burns, knife cuts, abrasions and other cuts, falling objects, head injuries and eye injuries. Some other items might include chemical exposures, insect/bee stings, poison ivy/oak/sumac and golf cart injuries.

The day of the week and time of the day categories can assist with trend recognition. Are the majority of events happening at the beginning of the workday or at the end of the day? Was it an exceptionally hot or cold day? The day after payday? Days near a holiday?

As you develop your injury/illness spreadsheet, be sure to exclude the employees’ names for confidentiality reasons. However, it may be important to know if there are any patterns emerging with specific employees. Perhaps some are “ill” the first week of July every year. There may be patterns emerging with employees for whom English is a second language, indicating that additional training may be required for the particular hazard those employees are encountering.

Other questions that might have to be asked include: How long have the employees been on the job? Are they new employees? Are they adequately trained?

Looking for Trends and Learning from Past Events

When reviewing your past injuries/illnesses records, determine if there is a common area where the incidents are happening or a particular process that can be changed to eliminate additional events from occurring. Be proactive, not reactive, when addressing incidents. Don’t automatically assume that because there is a pattern of head, arm, or hand injuries that employees must wear gloves, hard hats, etc.

Visit the site where the incident occurred and consider the factors leading to the injury. Ask the questions: who, what, where, why, when and how? Were there any special circumstances at the time? Did your kitchen have a significant number of knife cuts? Are the bartenders cutting their fingers because they don’t have a proper knife/cutting board? Would a knife safety training program help?

The club should also discuss injuries. According to Industrial Accident Prevention: A Scientific Approach, for every disabling injury there were 29 first aid incidences, preceded by 300 near misses. That means there were 329 opportunities to save one person from the pain and suffering experienced from a disabling injury. It must be noted that not all safety professionals ascribe to this safety interpretation.

The Safety Budget

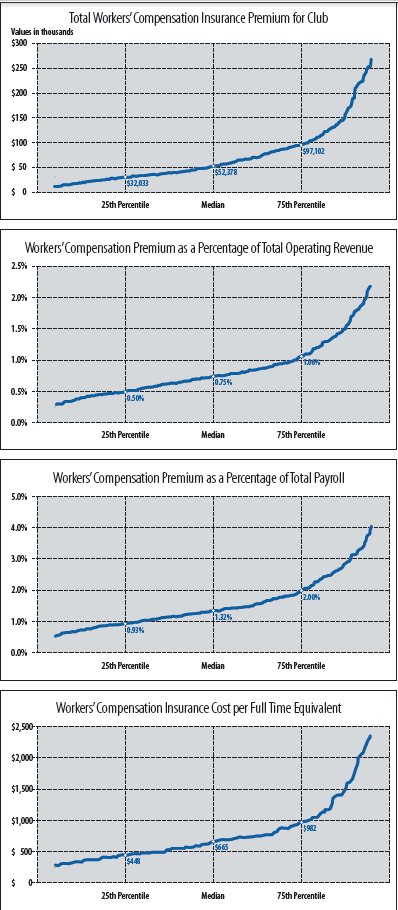

How much money should clubs use to fund a safety program? One method is to look at your workers’ compensation premium and use a percentage (10%, 15% or maybe 20%) to get the program underway. See the graphs from Club Benchmarking for club workers’ compensation costs at right. According to OSHA, an effective safety and health program saves time and money— about $4 for every $1 spent.

Clubs, like many other businesses, have experienced difficult times. Budgets have been cut, preventative maintenance programs deferred and capital expenditures delayed. Some of the ways to make sure your club has an effective safety program may include contacting your insurance provider to enlist their assistance with training, as they often have a library of safety videos. A club may conduct a worksite self-inspection, and OSHA offers on-site consultations by state agencies as well.

Successful education programs may eliminate or reduce potential future incidents. In addition, lowered insurance premiums from fewer employee incidences can show that the ongoing training is effective and provides cost savings.

Items to include in the club safety budget are: personal protective equipment, training videos and classes/sessions, wages for employees being trained, consultant fees and cash and/or prizes for rewards and incentives.

The Club Safety Committee

Forming a Safety Committee will help create continuity and accountability for your safety program. The Safety Committee should be comprised of both club management and employees—especially those who are safety champions. It is important to get the most positive employees involved and develop a team around them.

Who is knowledgeable when it comes to safety? Do you have any employees who are emergency medical technicians, retired police officers, spouses who work in the medical profession or who used to be employed as safety professionals? Are there any members of the club whose services could be used?

Make sure the committee size is manageable—choose from six to 10 members. Consider involving all the departments by inviting a representative from each to serve on a rotating basis, or perhaps use an ad hoc committee to solve a particular concern.

The Safety Committee should have a written mission statement and clearly defined duties and responsibilities. One goal should be to increase awareness of employees in safety matters as well as to make health and safety activities an integral part of the club’s operating procedures, culture and program. The committee should conduct regular safety audits of the property, identifying hazards and making recommendations for corrective measures or training to prevent repeat injuries.

Accident investigation is always a concern. It is possible that individuals may not speak up as to avoid negative consequences or punishment. Are the employees afraid of being blamed? Is the root cause being diligently sought? Dedicate the time to perform a proper investigation and be sure the staff is properly trained on how to conduct an accident investigation.

The first step in investigating an accident is to look at the circumstances:

- Who was involved?

- What tasks led up to the event?

- What tools were being used?

- How were the tools being used?

- Was the person involved properly trained on how to use the tools?

- When did the incident occur? (Beginning of the day? Beginning of the workweek?)

- Where did the incident occur?

- Is there an environmental factor that precipitated the event?

Each incident offers an opportunity to correct the situation whether it is an unsafe act by an employee, a training issue, design problem, faulty tool or perhaps a lack of awareness. It is important for the supervisors to have a level of trust with the employees. Employees must be comfortable approaching the supervisor on any issue. In addition, employees need to believe that if they approach the supervisor or manager, their concerns will be taken seriously and addressed.

Knowing what happened leads to finding out how it happened and, hopefully, preventing the event from happening again.

Safety Committee Activities

Some states have regulatory requirements for establishing safety teams and mandate the frequency of meetings. Monthly committee meetings are recommended and should include regular updates on safety issues and the progress toward completing action plans. A Safety Committee member also should be included in all accident investigations.

Safety Committees can get stale or possibly even lose their focus. Management should regularly review the committee’s meeting minutes, offer input and provide any necessary guidance. Changing and/or rotating team members might also provide new perspectives.

Communications

The Safety Committee can determine various ways to share what they are doing with all departments and staff members. Some ideas might be a newsletter sharing the minutes, a topic of the month, seasonal concerns, safety ideas for the home or perhaps even a case study. It is important that the committee does not reveal the identity of any injured employee, lest they lose their credibility or initiate a lawsuit.

The committee should also communicate safety concerns with employees (near misses/close calls) and recognize service, participation and engagement in the club safety program.

Finally, club management should share safety concerns with all new employees.

Starting a safety program isn’t an easy task. Recognize it takes time, resources and commitment. Additional information about workplace safety can be found in NCA’s publication, HR Management: Best Practices for Private Clubs, available online at nationalclub.org.

Alan Achatz, CCM, CHE, of Club Safety Solutions is a former club manager who has been operating a safety consultancy since 1997. He is an OSHA general industry outreach trainer who helps clubs with hazard recognition, emergency action planning, OSHA compliance, safety audits and food safety. Club Safety Solutions will provide NCA members a 30-minute free consultation. He may be reached at 716-565-9122 or at clubsafetysolutions.com.